WASCOMAT WASHERS

Wascomat is the Standard of Quality in the Laundry Industry!

Wascomat is the world's largest manufacturer of commercial and industrial laundry equipment

with over 90 years of experience. Wascomat laundry equipment is specifically designed to

meet the on-premise laundry needs of hotels, motels, hospitals, nursing homes, manufacturers

and food processors, schools, health clubs, restaurants, diaper services, and shirt laundries.

As linen rental costs soar, managers across the United States, Canada, Mexico and

worldwide are processing their laundry in-house with professional Wascomat laundry

systems, which provide outstanding cost savings.

Wascomat. Built to last a generation!

All Wascomats are built to last a generation. Durable stainless steel construction and the

fewest moving parts ensure near maintenance-free operation. Wascomats feature

state-of-the-art controls for easy operation and long machine life. Wascomat's hard-mount

(bolt-down) or soft-mount (no bolt-down) models means your Wascomat laundry can be

installed wherever you have space, even on upper floors, and can be customized to suit your

needs. Compact design saves floor space.

Cut Operating Costs:

Wascomat washers are engineered for efficient use of water, energy and chemicals for

maximum savings. Whether you use liquid or powder chemical supplies, Wascomats

produce superb wash results on all cotton, blend, polyester and VISA fabrics.

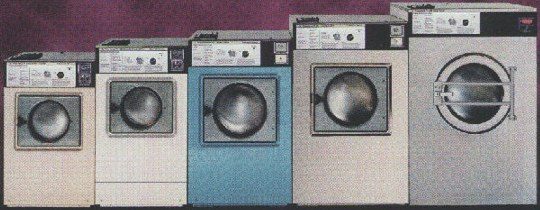

W-Series Washers

Classic Wascomat W-Series washers feature the rugged, durable construction and

electromechanical controls which have made these Wascomats the world's

best-selling, front-loading commercial washer for professional coin-operated

laundromats and washaterias. That's no idle claim - it's the truth! Appliance type

top-loading washers are designed for home use, not the abuse, overloading, and

constant duty of commercial use.

5 year warranty on zinc galvanized frame and cylinder; 2 year warranty on

all major parts.

Aircraft quality unibody construction totally eliminates welds for superior

strength, reliability and durability.

Built-in supply injector and wash cycle options to reduce time, water and energy

consumption.

Three inch, front-mounted hydraulic drain valve reduces clogs.

Single motor drive with self-adjusting belts.

Cast back gable and bearing housing for long machine life.

Unique wire harness with "quick disconnect" plugs simplifies service.

Positive door-lock system. Door open immediately upon wash cycle completion.

Professional wash formulas - hot, cold, warm, and permanent press.

Choice of front panel colors: Almond, blue, white, or stainless steel.

State-of-the-art Wascomat technology means fewer parts and easy maintenance.

Interchangeable parts from one size and model machine to another.

Copyright © 1999-2020 Centennial Distributing Corporation